Products

KWD Rail Coupling

KWD company is located in Dresden, Germany. Founded in 1887, it is a company specializing in the manufacture of couplings and occupies a special position in the German machinery industry. The company's products cover a wide range of fields and have the world's advanced technology. We focus on customer needs, provide high-standard, high-quality products, with certain competitive advantages, known as the German coupling expert.

KWD was awarded Q1 supplier by Deutsche Bahn and is currently the only manufacturer in Europe that can provide couplings for all rail vehicles.

The production capacity of rail transit couplings is 30,000 sets per year.

Application areas:

High-speed trains, subways and light rails, trams and trolleybuses, electric locomotives, rack cars, passenger cars

Brief Product information

I、Input coupling

1、Drive unit for flanged connection of two-bearing traction motors and gearboxes

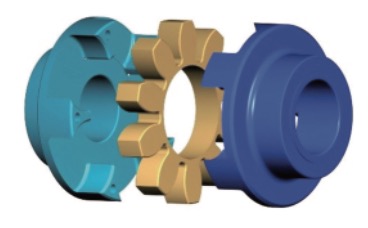

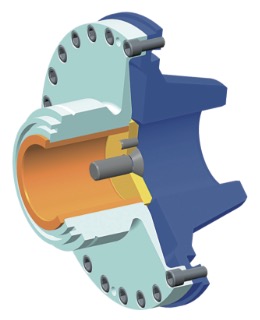

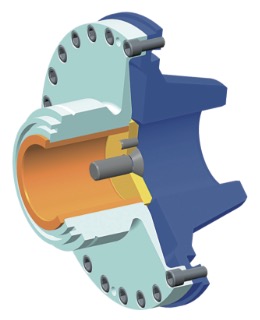

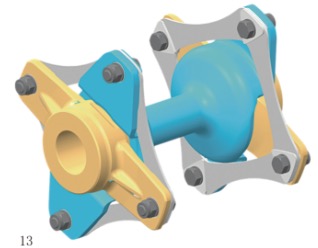

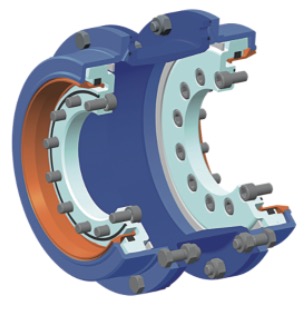

Star elastic coupling(EZK)

·Has torsional and bending stiffness

·Compensation of radial displacement, axial displacement and angular displacement through star-shaped elastic elements

·Blind assembly

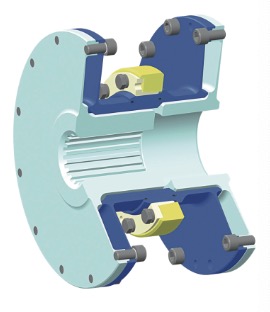

Double Membrane Disc Coupling (MEM)

Double diaphragm coupling can be equipped with torque limiter

-Dual gimbal for torsional and bending stiffness

·Compensate for radial and angular displacements by thin-walled profiles of the diaphragms on both sides

-Compensate for small radial displacement through the diaphragm on both sides

-Configurable torque limiter

-No wear

Duplex coupling: star elastic-diaphragm coupling (EZK-MEM)

·Have the dual characteristics of EZK type coupling and MEM type coupling.

-Compensate for radial displacement and angular displacement through the thin-walled profiles of the diaphragms on both sides

-Axial displacement is compensated by star-shaped elastic coupling

·Blind assembly

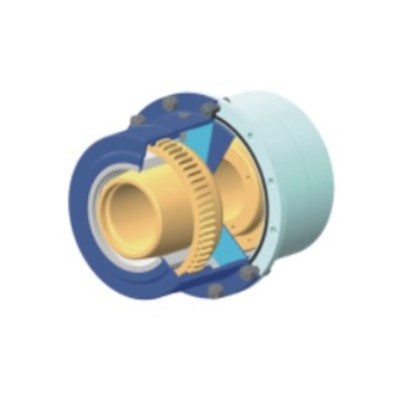

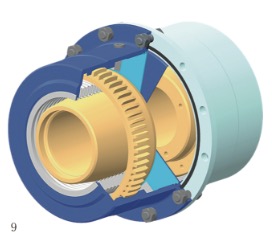

Gear Coupling (ZK)

Oil bath lubrication, no seals

·Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics

-Compensate for axial displacement, radial displacement and angular displacement

-Integrated in the drive unit (gearbox), oil bath lubrication, no seals

2、Drive unit for flanged connection of single bearing traction motor to gearbox

Diaphragm Coupling (MEM)

Single-diaphragm disc, the hubs on both sides are connected with the shaft by interference

-Has torsional and bending stiffness

-Compensate for small axial and angular displacements

-High radial stiffness

-Overload protection by slip bushing

-No wear

Spiral tooth end tooth double diaphragm coupling (MEN)

Double diaphragm, one side interference connection, one end face tooth connection

-Has torsional and bending stiffness

-Compensate for small axial and angular displacements

-igh radial stiffness

-No wear

Diaphragm Coupling (MEM)

Single-diaphragm disc, the hubs on both sides are connected with the shaft by interference, with insulating function

-Has torsional and bending stiffness

-Compensate for small axial and angular displacements

-High radial stiffness

-Slip bushing is optional to realize overload protection function.

-No wear

Diaphragm Coupling (MEM)

Single-diaphragm disc, the hubs on both sides are connected with the shaft by interference

-Has torsional and bending stiffness

-Compensate for small axial and angular displacements

-High radial stiffness

-With fan function

-Integrated labyrinth seal structure

-No wear

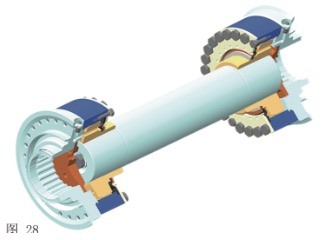

3、For semi-suspension drives

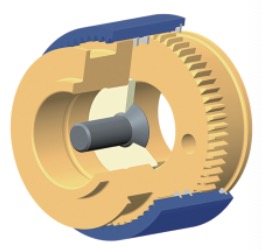

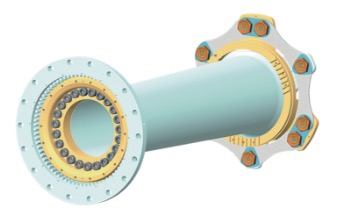

Gear Coupling (ZK)

Adopt metal bellows seal patent structure, oil lubrication is recommended

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics.

-Large compensation capacity of axial displacement, radial displacement and angular displacement

-Complete sealing of the coupling through metal bellows

-Thanks to the good sealing structure, the lubricating oil replacement cycle is long (long maintenance-free cycle)

-the lubricating medium can be replaced without disassembly (applicable to lubricating oil)

-Self-lubricating (applicable to lubricating oil or grease)

-Optional sliding bushing realizes overload protection function

-Optional insulation function

Gear Coupling (ZK)

Elastomeric seal

-Double gimbal, with torsional stiffness, self-centering gear teeth, high specific power characteristics

-Compensate for axial displacement, radial displacement and angular displacement

-Grease lubrication

-Optional sliding bushing realizes overload protection function

-Optional insulation function

Gear Coupling (ZK)

Before leaving the factory, the slip torque is pre-adjusted by the manufacturer according to the technical requirements

-Double gimbal, with torsional stiffness, self-centering gear teeth, high specific power characteristics

-Compensate for axial displacement, radial displacement and angular displacement

-Self-lubricating (applicable to lubricating oil or grease)

Gear Coupling (ZK)

Adopt metal bellows seal patent structure, oil lubrication recommended, connecting flange, with torsional rigidity

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power, transitional elastic element for adjusting stiffness

-Compensate for axial displacement, radial displacement and angular displacement

-Complete sealing of the coupling through metal bellows

-Thanks to the good sealing structure, the lubricating oil replacement cycle is long (long maintenance-free cycle)

-The lubricating medium (lubricating oil) can be replaced without disassembly ··Self-lubricating (applicable to lubricating oil or grease)

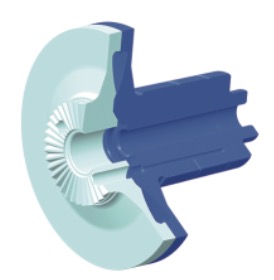

Flexible Laminated Couplings (SRS)

-Dual gimbal for torsional and bending stiffness

-Compensation of axial, radial and angular displacement through flexible lamination assemblies

-No wear

-Optional insulation function

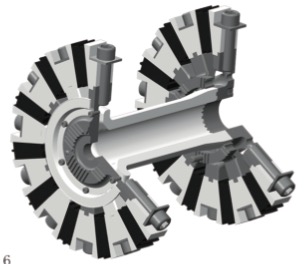

4、For hollow shaft drives

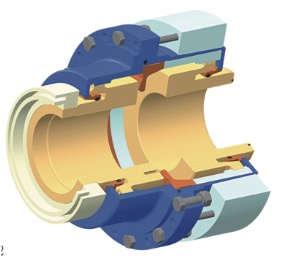

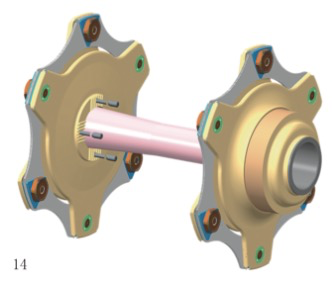

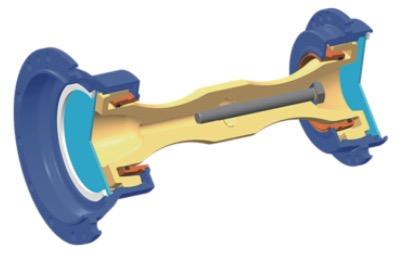

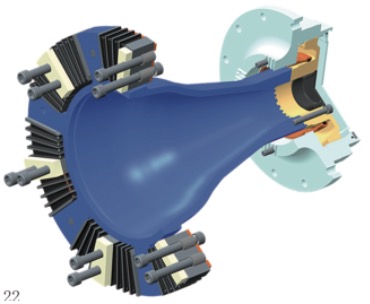

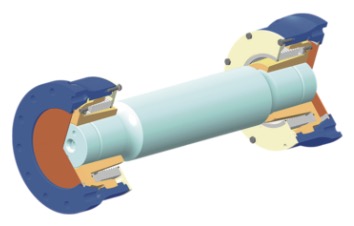

Flexible Laminated Couplings (SRS)

Gearbox hollow shaft coupling or traction motor hollow shaft coupling

-Dual gimbal for torsional and bending stiffness

-Compensation of axial, radial and angular displacement through flexible lamination assemblies

-Through the gearbox or motor, saving installation space

-No wear

-Optional insulation function

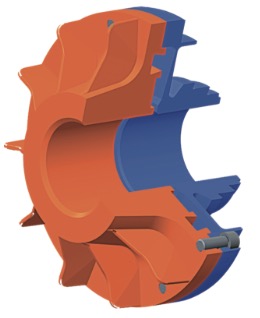

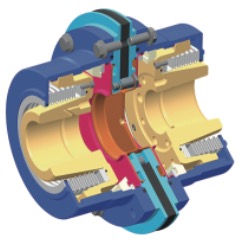

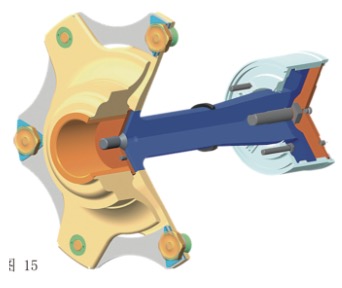

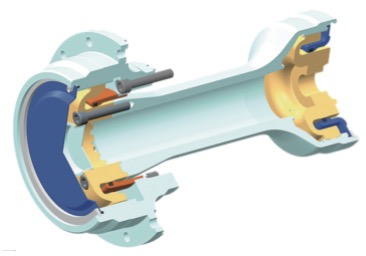

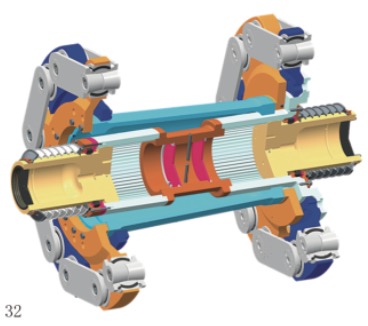

Duplex Coupling

Gear-Flexible Laminated Coupling (ZK-SRS)

Gearbox hollow shaft coupling or traction motor hollow shaft coupling

-Double universal, with torsional stiffness, bending stiffness and gear teeth self-centering, high specific power characteristics

-Compensate for radial displacement, axial displacement and angular displacement

-Compensation of large axial displacement by gear half coupling

-The use of flexible lamination couplings and gear half couplings integrated in the gearbox saves installation space

-Less maintenance

-Optional insulation function

II、Output coupling

1、for full suspension drives

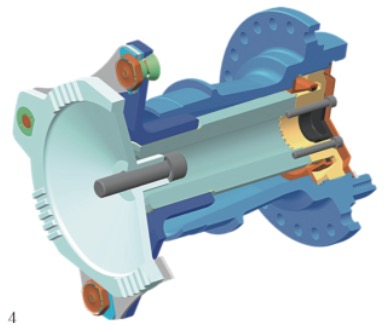

Link Coupling (LK)

-Dual gimbal for torsional and bending stiffness

-Compensate for large radial displacement, axial displacement and angular displacement through connecting rods on both sides

-Suitable for high-power railway locomotives

Duplex Coupling

Gear-Flexible Laminated Link Coupling (ZK-SLK)

-Double gimbal, with torsional and bending stiffness, self-centering gear teeth

-Compensate for axial displacement, radial displacement and angular displacement

-Compensation of large axial displacement by gear half coupling

-Gearbox adopts hollow shaft design

-Adopt connecting rod type half coupling, saving installation space

-Less maintenance

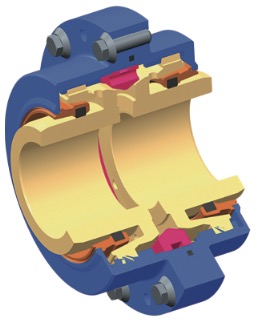

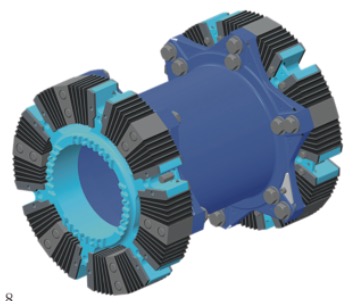

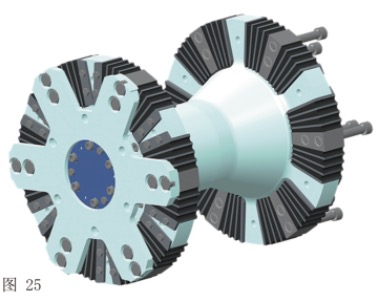

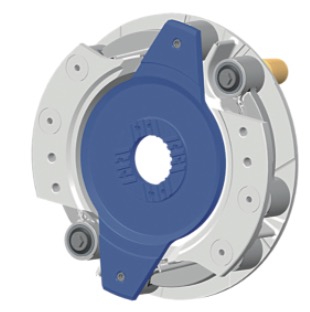

Rubber wedge coupling (KPK)

-Dual gimbal for torsional and bending stiffness

-Compensate for radial displacement, axial displacement and angular displacement, compact lateral space

-Replacement of rubber wedges without dismantling the drive

2、for semi-suspension drives

Rubber wedge coupling (KPK)

-Single gimbal with torsional and bending stiffness

-Compensate for angular displacement and axial displacement, compact lateral space

-High radial stiffness

-Replacement of rubber wedges without dismantling the drive

III、Suitable for low-floor tram drives

1、Gear coupling

Gear Coupling (ZK)

-Grease lubrication

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics

-Compensate for axial displacement, radial displacement and angular displacement

-Flange connection between gear coupling and gearbox hollow shaft

-Less maintenance

Gear Coupling (ZK)

Suitable for permanent magnet motor drives, grease lubricated

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics.

-ompensate for axial displacement, radial displacement and angular displacement

-Quickly disconnect and disconnect from the motor during maintenance

- Less maintenance

2、Duplex Coupling

Duplex coupling: gear-rubber wedge coupling (ZK-KPK)

-Has the dual characteristics of ZK type coupling and KPK type coupling.

-Compensate for axial displacement, radial displacement and angular displacement

-Axial displacement is compensated by single-sided gear coupling

-Flange connection between gear coupling and gearbox hollow shaft

-Directly connected to the wheel (independent wheel drive)

Duplex coupling: gear-ring rubber wedge coupling (ZK-KPR)

·Have the dual characteristics of ZK type coupling and KPR type coupling

-Compensate for axial displacement, radial displacement and angular displacement

-Axial displacement is compensated by single-sided gear coupling

-The gear coupling integrated into the hollow shaft of the gearbox saves installation space

-Direct connection with the wheelset through the face teeth

-The annular rubber can be designed with radial separation

Duplex Coupling: Gear-Flexible Laminate Coupling (ZK-SRS)

-Have the dual characteristics of ZK type coupling and SRS type coupling.

-The gearbox adopts an integrated design to save space

- Directly connected to the wheel

-Axial displacement is compensated by single-sided gear coupling

-Less maintenance

3、Rubber wedge coupling

Rubber wedge coupling (KPK)

-Double gimbal, with torsional and bending stiffness

-Compensate for axial displacement, radial displacement and angular displacement

-Gearbox adopts hollow shaft design

-Directly connected to the wheel

-Connect with gear box through face teeth

4、Ring rubber wedge coupling

Ring Rubber Wedge Coupling (KPR)

-Double gimbal, with torsional and bending stiffness

-Compensate for axial displacement, radial displacement and angular displacement

-Gearbox adopts hollow shaft design

-Direct connection to wheels or axles

-The annular rubber can be designed with radial separation

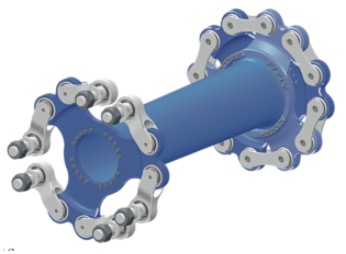

5、Connecting rod coupling

Link Coupling (LK)

-Designed with "Dancing ring"

-Features torsional stiffness and bending stiffness, compact axial installation space

-Compensate for axial displacement, radial displacement and angular displacement

-Installed directly between the gearbox and the wheel

6、Cardan shaft gear couplings for master-slave gearbox drive systems

Universal shaft gear coupling (ZKGW)

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics

-Compensate for axial displacement, radial displacement and angular displacement

-Self-lubricating (applicable to lubricating oil or grease)

IV、Suitable for monorail drives

Gear Coupling (ZK)

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics

-Drive unit suitable for inclined and inclined arrangement

-Large axial displacement, radial displacement and angular displacement capability

-Complete sealing of the coupling through metal bellows

-Thanks to the good sealing structure, the lubricating oil replacement cycle is long (long maintenance-free cycle)

-The lubricating medium can be replaced without disassembly (applicable to lubricating oil)

-Self-lubricating (applicable to lubricating oil or grease)

-Optional sliding bushing realizes overload protection function

-Optional insulation function

Gear Coupling (ZK)

-Shaft-hub connection: double-sided flange connection

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics.

-Compensate for axial displacement, radial displacement and angular displacement

-Special flange design

-Self-lubricating (applicable to lubricating oil or grease)

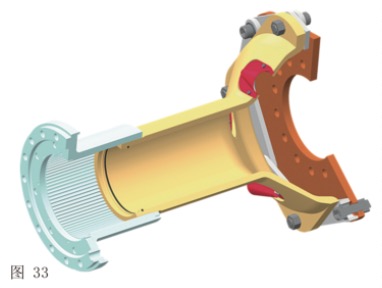

V、Universal shaft gear coupling

Universal shaft gear coupling (ZK)

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics.

-Constant speed operation

-Small reaction force

-Optional connecting shafts of different lengths

-Complete sealing of the coupling through metal bellows

-Oil lubrication is preferred

-Long lubricating oil replacement cycle (long maintenance-free cycle)

-The lubricating medium can be replaced without disassembly (applicable to lubricating oil)

VI、Suitable for variable gauge drive systems

Duplex Coupling

-Gear-Link Coupling (ZK-LK)

-Suitable for track gauge adjustment of moving wheels

-Have the dual characteristics of ZK type coupling and LK type coupling

-Compensate for large axial displacement when passing through the gauge adjustment device

-Connect directly with wheel interference

-Self-lubricating (applicable grease)

Double coupling

-Gear-Flexible Laminated Link Coupling (ZK-SLK)

-Have the dual characteristics of ZK type coupling and SLK type coupling.

-Compensate for axial displacement, radial displacement and angular displacement

-Gear type half-coupling is directly connected with the gearbox to compensate for large axial displacement.

-Adopt connecting rod coupling structure, compact installation space

-Self-lubricating (applicable grease)

Gear Coupling (ZK)

-Suitable for trailer bogies

-Double universal, with torsional stiffness, self-centering gear teeth, high specific power characteristics.

-Compensate for radial displacement, axial displacement and angular displacement

-High axial compensation capability

-Self-lubricating (applicable grease)

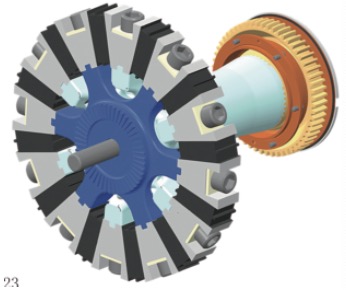

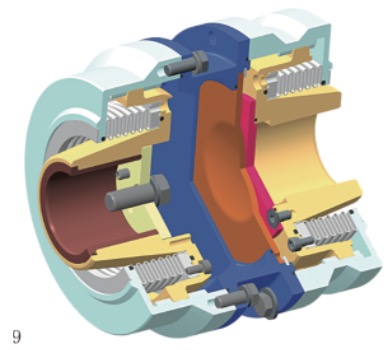

VII、Elastic coupling

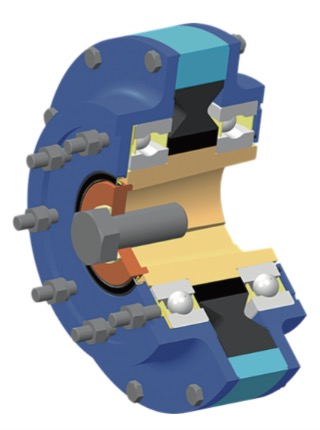

Elastic Couplings (VSK)

-Including roller bearings

-High elasticity, with vibration damping function, suitable for connecting cardan shafts ·

-Strong damping performance

-Integrated overload protection function

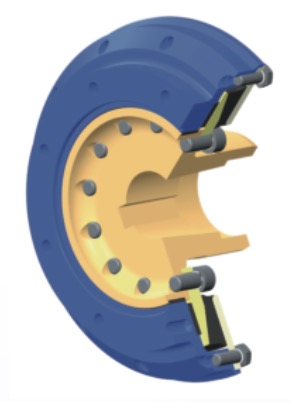

Elastic Couplings (VSK)

-With sliding bearing

-High elasticity, with vibration damping function, suitable for connecting cardan shafts