Product R&D

Product R&D

At present, oil-free air compressors are improved and developed on the basis of oil-air compressors. There are two main ways: the first is water-lubricated; the second is self-lubricating of materials or coatings.

It is more and more widely used in fields with higher requirements for compressed air, such as: gold plating, copper plating, medical, food, laboratory, electronics, chemical, mining and other industries.

In the field of rail transit, the second method is adopted as an oil-free air compressor for locomotive and vehicle braking. Globally, European railways are widely used; domestic applications are in their infancy. In the domestic subway (Qingdao Metro Line 3), KB has been used in batches.

Oil-free air compressor in use:

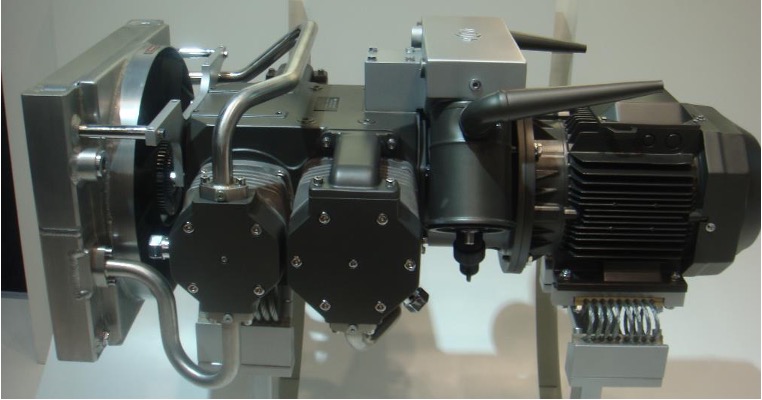

AC- oil-free scroll air compressor

KB-Oil-free piston compressor

Oil-free scroll air compressor

Oil-free scroll air compressor technology is the best way for small-displacement air compressors. It has the structural characteristics of energy saving, quietness and high reliability. There is no metal contact except the bearing. The oil-free scroll air compressor has few complete components, plus a motor, air filter, and rear-cooling to form a complete compression system.

Oil-free scroll air compressors, also known as fourth-generation compressors, have many advantages in the compressor industry:

| Items | Oil-free scroll air compressor |

| Compression principle | Two involute dynamic and static scrolls are mutually engaged to complete the working processes of suction, compression and exhaust, which can be applied to the working cycle from 0% to 100%. |

| Vibration, noise | When working, the dynamic and static scrolls do not touch, and there are no suction and exhaust valves and complex motion mechanisms, which eliminates the knocking sound of the valve plate and the blasting sound of the airflow, and the suction and supply are stable, with low vibration and low noise. |

| Maintenance and repair | The main engine has few parts, the dynamic and static scrolls do not contact, the whole machine has no wearing parts, and only the air filter needs to be replaced; in the whole life cycle, it only takes 1.5 hours per year for preventive maintenance, including overhaul; it has a very short life cycle cost characteristics. |

| High reliability | Simple structure, less main engine parts, less than 1/6 of the number of screw machines; no lubricating oil, no emulsification risk; no oil/carbon pollution in the air system, long service life. |

| Energy saving, environment friendly | The air compressor with the highest energy efficiency ratio; the compressed air is oil-free, and there is no need to replace the lubricating oil and its oil filter, and there is no problem of waste liquid disposal; at the same time, it avoids the oil leakage of the body and the impact of oil change on the environment. |

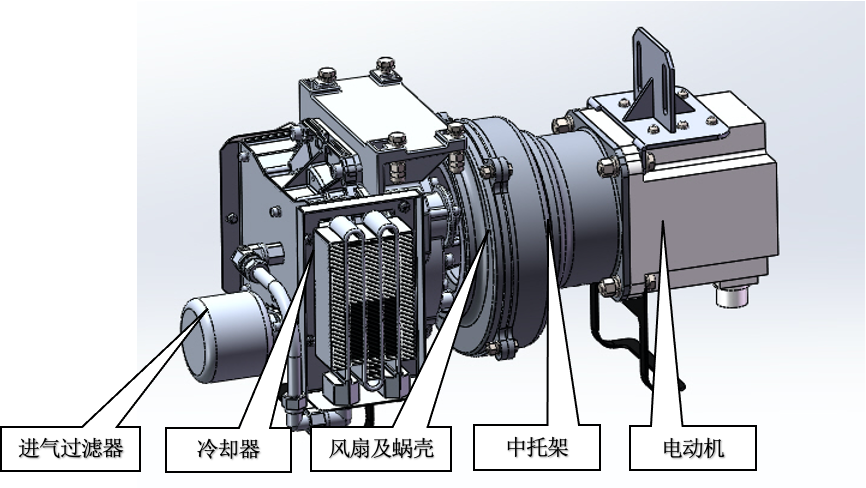

SFR series oil-free scroll air compressor

| Model type | Max. emission | Rated exhaust volume | Used on |

| SFR-0.3 | 0.30 m3/min | 10bar | single rail series |

| SFR-0.6 | 0.60 m3/min | 10bar | light rail、maglev |

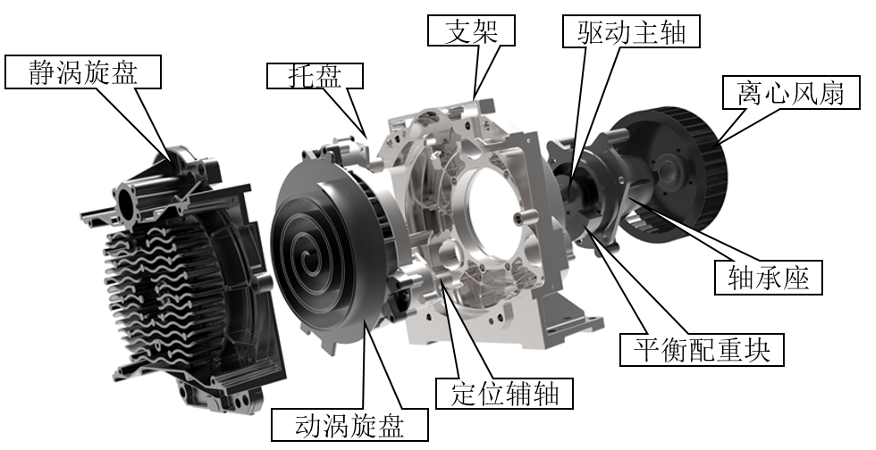

Working principle of oil-free scroll air compressor

The movable scroll rotates in the order of Fig. 1→2→3→4→5, the air is sucked into the space between the movable scroll and the fixed scroll, the volume of the crescent-shaped compression chamber gradually decreases, and the air passes through the space. After compression, it is discharged from the exhaust port at the center of the static disc, as shown in the following figure: the dark part is the compressed air.

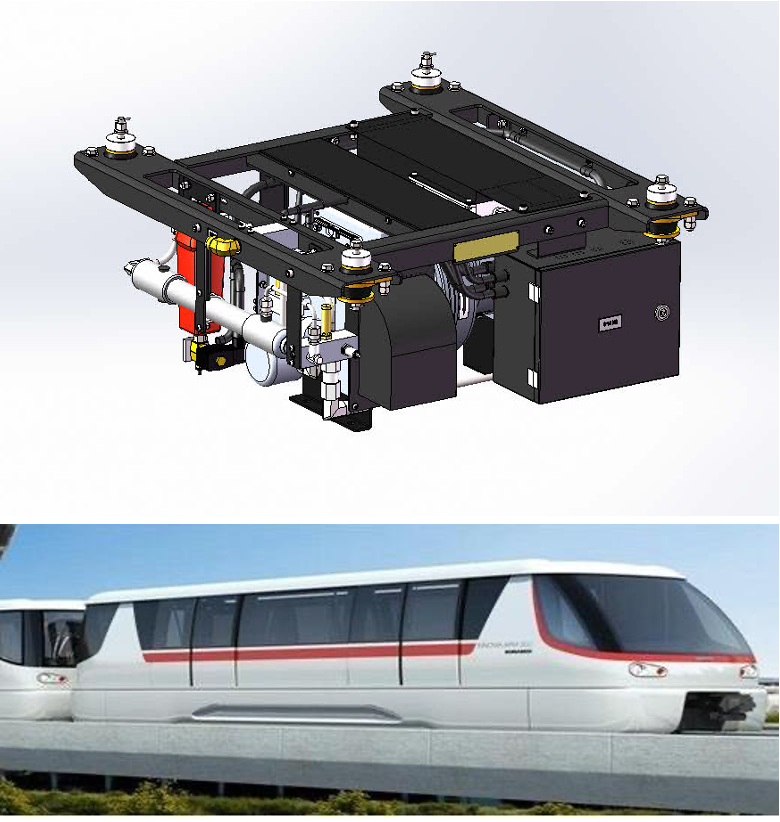

Bombardier APM300 Brake Air Source

| main parameters | Unit | values |

| Air supply unit model | / | ASU-0.3-01 |

| Nominal volume flow after dryingm3/min | ≥0.225 | |

| Rated exhaust pressurebar | 10 | |

| Working pressure rangebar | 9~10 adjustable | |

| Outlet safety valve setting | 11bar | |

| air quality class | ISO 8573-1 2 | |

| Compressed air relative humidity | % | ≤35(dew point drop-40℃) |

| Working temperature | ℃ | -25~50 |

| Relative humidity of working environment | % | 0~100 |

| sound pressure level at 7.5m | db(A) | ≤65 |

| cooling method | / | full air cooling |

| working cycle | / | 5%~100% |

| working mode | / | Start/stop |

| power supply | V/Hz | 3AC 240±10% / 60 |

| motor rated power | kW | 4 |

| motor rated speed | r/min | 2850 |

| Protection class(Electric) | / | IP65 |

| control power | V | DC 24(-30%~+25%) |

| exhaust outlet | inch | 3/4 |

| mass | kg | ≤110 |

| hanger paint | / | RAL9017 |

Bombardier APM300 Brake Air Source Third Party Test Report

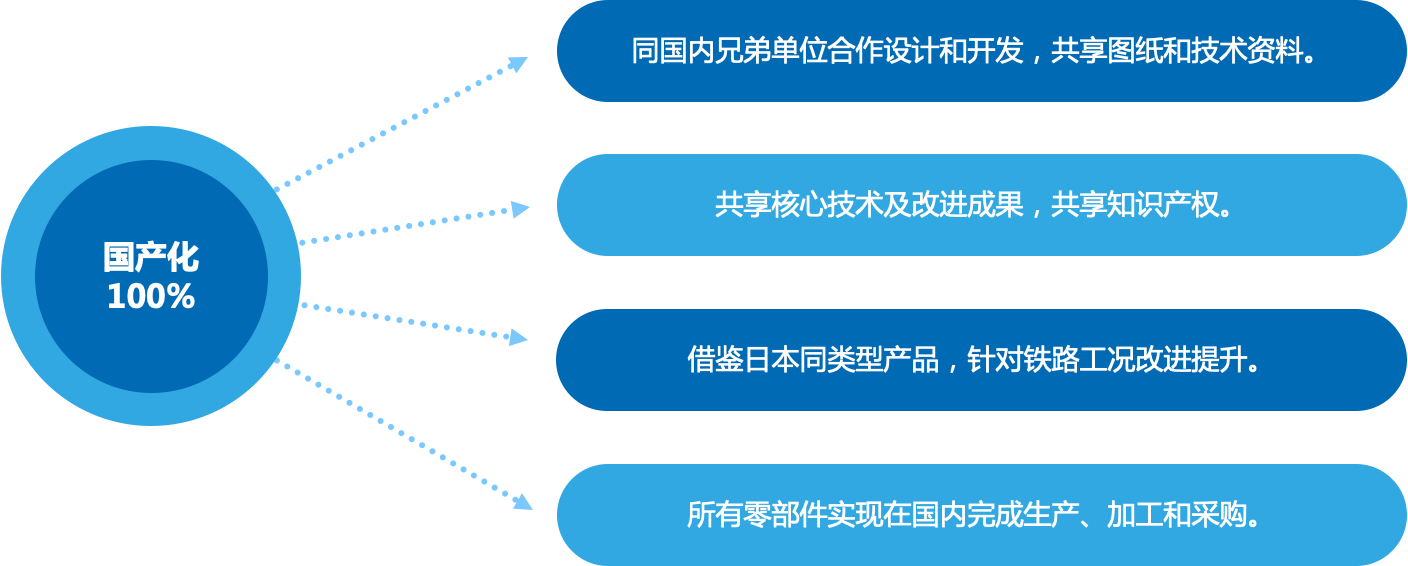

100% localization via following ways:

Cooperate with domestic partner companies in design and development, share technical drawings and documents.

Share core technical fruits and improvements, share knowledge property.

Learn from similiar Japan products, improve on railway work conditions.

Realize production, further processing and procurement of all components and parts domestically in China.

Oil-free piston air compressor

Advantages:

Reduced scheduled maintenance - no lube checks, no lube refills, no lube and filter changes

Improved air dryer performance - better compressed air quality, fewer pre-filter settings, longer desiccant life

No more dealing with classified and restricted substances - oils, drains, filters

Reduce the impact on the environment---compressed air is oil-free, no need to replace lubricating oil and its filter, no waste liquid disposal problem, and avoid oil leakage from the body

No need to install a drain tank on the locomotive or vehicle

Lower energy consumption---better thermal efficiency, no oil circulation, no viscous friction

Able to adapt to very low temperature conditions - run without oil, no increase in viscosity

No problem with low operating rates --- water does not condense in oil

Higher reliability---reduce 60% failures directly or indirectly caused by lubricating oil

Lower full life cycle (LCC) cost---annual average cost equivalent to 55% of oil-piston air compressors and 65% of oil-injected screw compressors

Oil-free piston air compressor

Advantages:

Reduced scheduled maintenance - no lube checks, no lube refills, no lube and filter changes

Improved air dryer performance - better compressed air quality, fewer pre-filter settings, longer desiccant life

No more dealing with classified and restricted substances - oils, drains, filters

Reduce the impact on the environment---compressed air is oil-free, no need to replace lubricating oil and its filter, no waste liquid disposal problem, and avoid oil leakage from the body

No need to install a drain tank on the locomotive or vehicle

Lower energy consumption---better thermal efficiency, no oil circulation, no viscous friction

Able to adapt to very low temperature conditions - run without oil, no increase in viscosity

No problem with low operating rates --- water does not condense in oil

Higher reliability---reduce 60% failures directly or indirectly caused by lubricating oil

Lower full life cycle (LCC) cost---annual average cost equivalent to 55% of oil-piston air compressors and 65% of oil-injected screw compressors

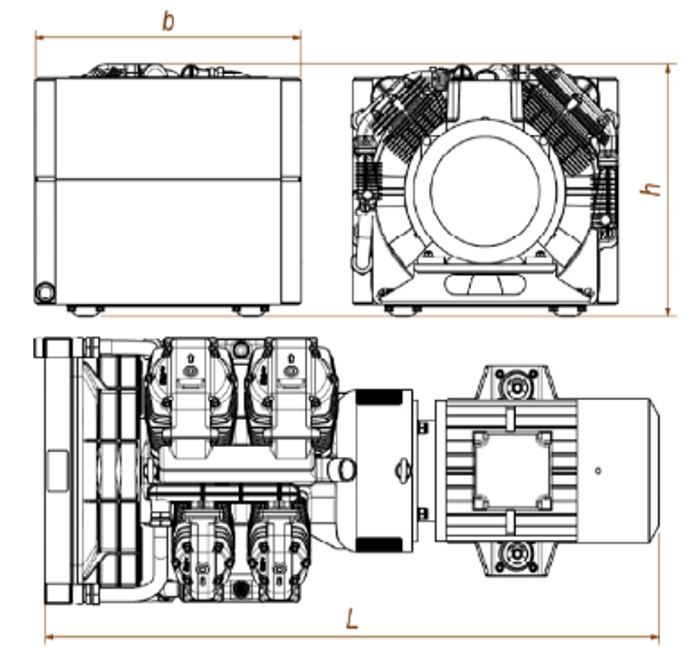

PFR Series Oil-free piston air compressor

Application | Motor | 50Hz | 60Hz | ||

| emission | Power consumption | emission | Power consumption | ||

Standard metro | Class 6 motor | 0.9~1.0 m3/min | 9KW | 1.1 ~1.2 m3/min | 11KW |

| Locomotive | Class 4 motor | 1.4~1.5 m3/min | 14KW | 1.7 ~1.8 m3/min | 16.5KW |

| Dimensions:(L)1345mmx(b)590mmx(h)460mm | mass:260kg | ||||

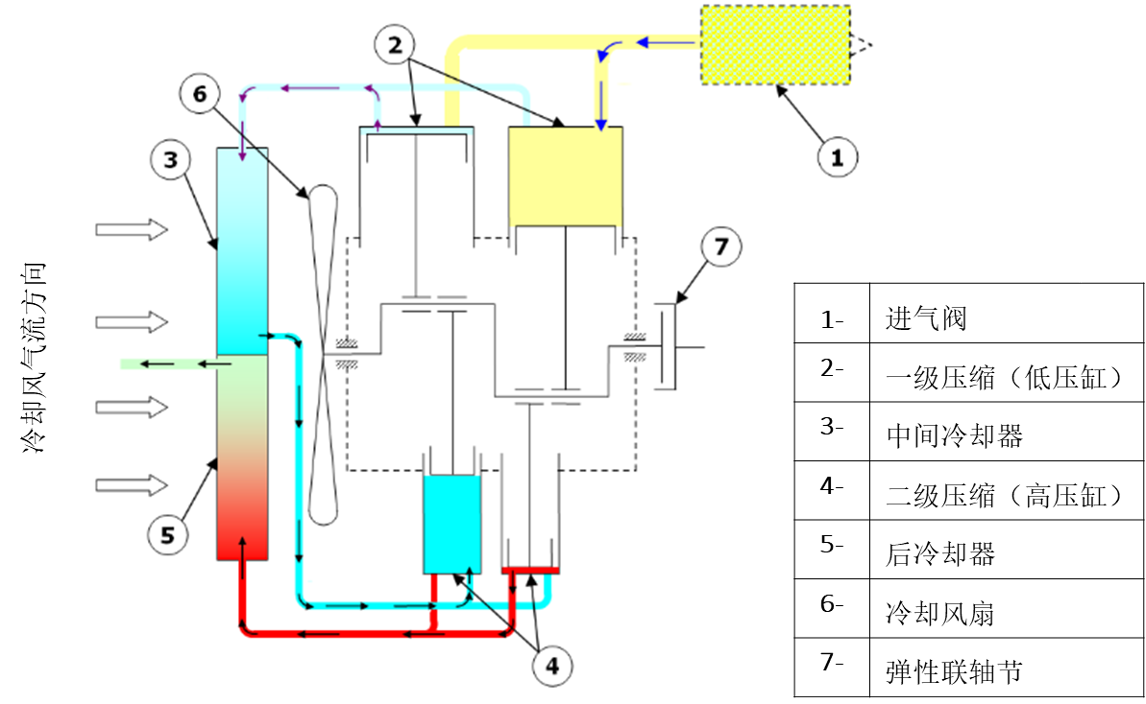

Structure and Principle Introduction

Technical specification:

| work cycle allowed | 0~100% |

| working ambient temperature range | -55℃~60℃ |

| Maximum ambient humidity allowed | 99% |

| range of rotation | 960r/min~1800r/min |

| outlet compressed air temperature | ambient temperature+10℃ |

Lab testing site

reliability growth test(ground)over2000h

still ongoing

Main structure features

Cylinders, pistons and crankcases are cast from aluminium alloys - reduced mass

Special hardening treatment on cylinders - increased thermal efficiency and reduced friction

Patented material sealing ring---wear amount 0.2mm/10000h, to ensure longer service life

Sealed Long Life Roller Bearings - Use Special Lubricants to Ensure Wide Temperature Range

One-piece connecting rod --- reduce the mass of the reciprocating motion

Reed Cylinder Valves - High Dynamic Response Over Wide Operating Speed Range

Combined heat exchanger (intercooler + aftercooler)---high thermodynamic efficiency of air cooling

Axial cooling fan---directly driven by compressor shaft

Elastomeric coupling for motor connection

The high and low pressure cylinders adopt 4-cylinder "V" type opposites---minimize the vibration caused by the unbalance during operation

Low speed motor - lower noise level

Tips:

The main functions of lubricating oil in oil-filled air compressors are: sealing, lubrication, cooling and noise reduction.

Because of its structure and oil-free characteristics, oil-free piston air compressors have poorer performance in terms of vibration and noise than oil-based air compressors, especially rotary air compressors.

So far, through the continuous improvement of structure and materials, the vibration and noise of oil-free piston air compressors have approached or reached the level of oil-based rotary air compressors with the same displacement.

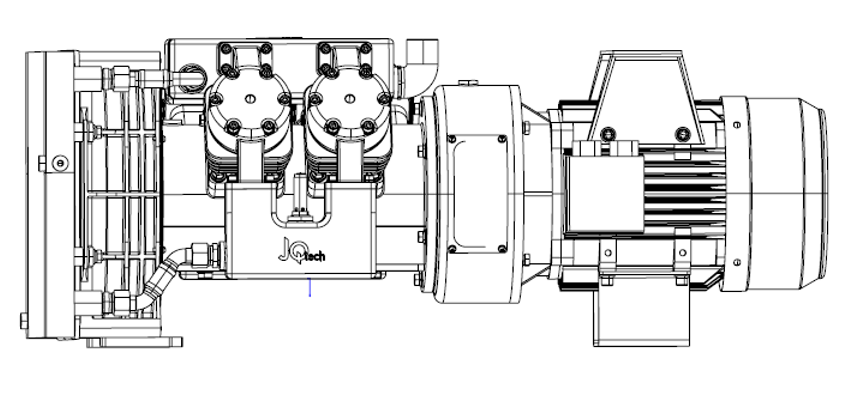

Main components and structural design

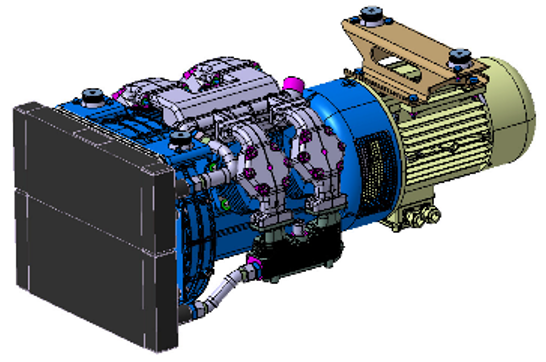

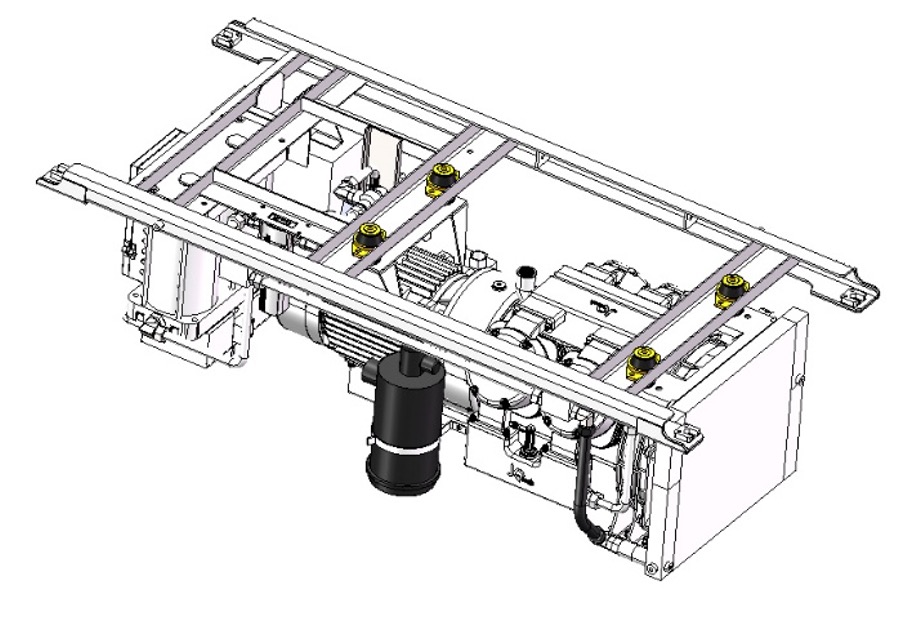

Product 3D model display

Oil-free piston AC

Standard metro air source device